I found an interesting chart that differentiates the different types of metal compositions using lead in producing type for printing:

“While often referred to as ‘lead type,’ type is, in fact, a variable alloy of 54-86% lead, 11-28% antimony and 3-18% tin. Antimony hardens the metal. Tin toughens the metal, counteracting the brittleness of antimony, as well as increasing the fluidity of the molten metal. The exact alloy chosen is based on the type of machine it is to be used in. As the antimony and tin increase in the type metal, the hardness and durability of the type also increases. The downside of this is that the casting temperatures also have to increase to keep the alloying elements in solution. Alloys with the lowest percentage of antimony and tin are used in non-water cooled linecasters, which run at the lowest pot temperatures. The alloys with the highest proportions of alloying elements are used in traditional foundry type, cast with high temperature and pressure sorts casters such as the Barth Typecaster. Even the highest casting temperatures are well below the ‘boiling’ point of lead, thus molten type metal does not produce lead fumes — a detail often misunderstood by the public.” (https://letterpresscommons.com/type-founding/)

The composing stick I showed yesterday was used for “traditional loose hand set type” (mentioned on the bottom row of the chart above). The letters were already formed and raised from their base; they needed no further work and could be printed once they were assembled into words (type reads “Joseph Papin Artist”):

Unlike the loose type where the raised letters are already ready to be printed, both the Ludlow and the Linotype mats or matrices are indented below the surface. They are both molds of the letters that need to be filled up with metal to form raised letters in order to be printed.

The matrices shown below (two lying down and the one in the middle propped up between them to show the letter “J”) are used to make the various letters and symbols that form the “line-of-type” that a Linotype machine makes:

The “J” is shown on its side below:

The Ludlow is similar in that the letters will be filled with lead. It is also a mold for producing a larger word or short phrase, in a fashion similar to how the Linotype matrices are filled with lead to form the line-of-type:

(I only had one lowercase “s” so I used a capital “S” as my second “s.”) It’s easier to see that this is a mold when the letters are not already placed in the Ludlow composing stick so that you can see it from the side (as shown below):

After the letters were fitted into the composing stick, and if I had access to an actual Ludlow machine, the composing stick would be put directly into the Ludlow casting machine and the word “PresS” would be cast in lead. It was used for making titles or anything that needed really large letters such as headlines.

“The Ludlow Typograph Company was founded in 1906 by the machine’s inventor, William I. Ludlow, and machinist William A. Reade to manufacture a simpler, cheaper version of the Linotype. The Ludlow Typograph is a hot metal typesetting system used in letterpress printing. The system uses molds, known as matrices or mats, which are hand-set into a special composing stick. The device casts bars, or slugs of type, out of type metal primarily consisting of lead. These slugs are used for printing, and then are melted down and recycled on the spot. The true worth of the Ludlow lies in the fact that the printer always has fresh, clean type to print from, and never has to worry about running out of sorts.” (https://www.printmuseum.org/1970s-ludlow)

There is a good little two minute video showing it working that is quite interesting at https://m.youtube.com/watch?v=DI-xZdVdyyM

I greatly suspect that the title of the article, A Child’s History of Christmas, Sunday News, illustrated by Joseph Papin and published on December 21, 1969 was made using a Ludlow machine, partly because it is so large and partly because it is an irregular type. (It is also possible that is was hand-drawn by one of the calligraphers on staff, but even if this was the case in this instance, this title would be the type of thing that would have been caste on the Ludlow machine.)

The zinc plates are unmounted, and would have needed something holding them up to the correct level along with the lines of type that made up the story, just as the plate below needed the wood it was backed with in order to the same height as the text:

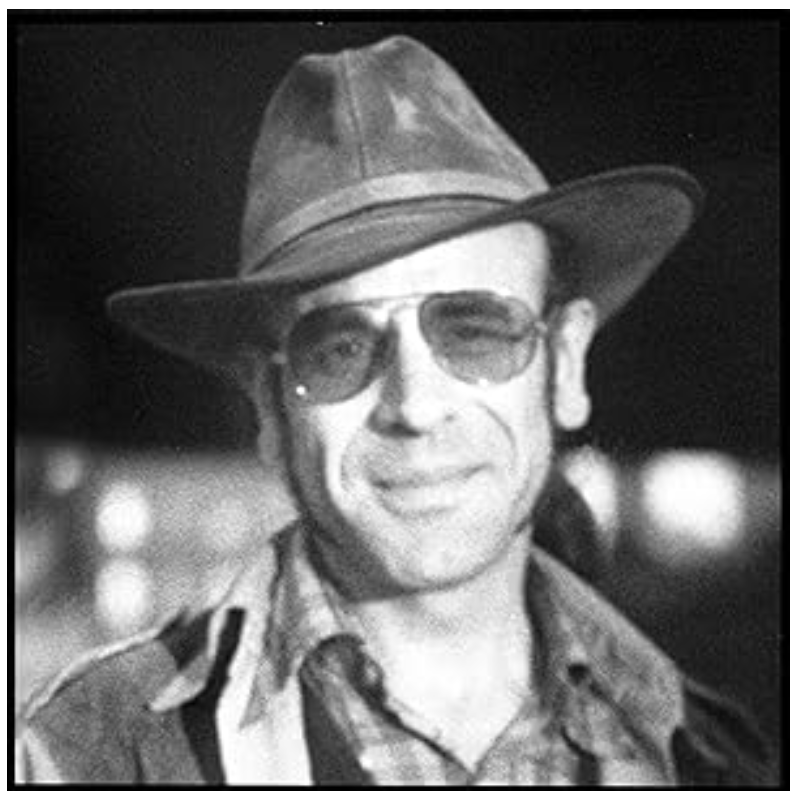

Richard Nixon by Joseph Papin (National Review, November 14, 1967).

Leave a Reply