The following drawing of a Linotype machine by Joseph Papin was done for the August 1958 issue of Harper’s Magazine on the New York Times. The New York Times stopped using their Linotypes in 1978 and switched to using computers; the Daily News got rid of their Linotypes in 1979, ending almost 100 years of hot-type printing.

“Linotype refers to a machine, power-driven, and manually-operated, that produces composed type on metal bars called slugs. Created and sold by the Mergenthaler Linotype Company, its first operation began in 1886 at the New York Herald Tribune. The word “line-o-type” derives from the fact that the machine produces an entire line of metal type at one time. An operator enters text on the keyboard and the machine assembles the matrices (small brass units having characters indented in the edges), which are molds for the letterforms in a line. The assembled line of text is cast as a single piece, known as a slug. The matrices are reused later if needed. The machines set type in hundreds of languages and dialects for books, periodicals, newspapers, and advertisements. The operator of the machine converted copy (typewritten or handwritten) into new type and cast type slugs.” (https://invention.si.edu/simple-operation)

The line of type that says “Joseph Papin” below is a slug. The letters, “W” and “H” are individual typesetting letters that he had in his collection of miscellaneous things.

The following photo shows a line of matrices and spacer bars that were used in a Linotype when casting a line of type. You can see the little letters on the front of the matrices that would be cast to produce the line of type:

(https://letterpresscommons.com/linotypeandintertype/)

“When the casting command is given, the spacebands are moved upward to create the correct line width, the entire assembly of matrices and spacebands is clamped tight to the mould, the line is cast and trimmed and delivered to the front of the machine. Then, the spacebands are mechanically sorted out and moved back to the spaceband box, where they will be re-used. The matrices are elevated to the top of the machine, then automatically sorted into the appropriate channel in the magazine via a system of teeth on the matrix. The sorting and and assembly of the matrices is powered entirely by gravity—only the casting and elevation of the matrices require mechanical assistance.” (https://letterpresscommons.com/linotypeandintertype/)

The Linotype was noted as “a significant improvement over the previous industry standard of letter-by-letter manual typesetting using a composing stick and shallow subdivided trays, called ‘cases’.”

(https://en.wikipedia.org/wiki/Linotype_machine)

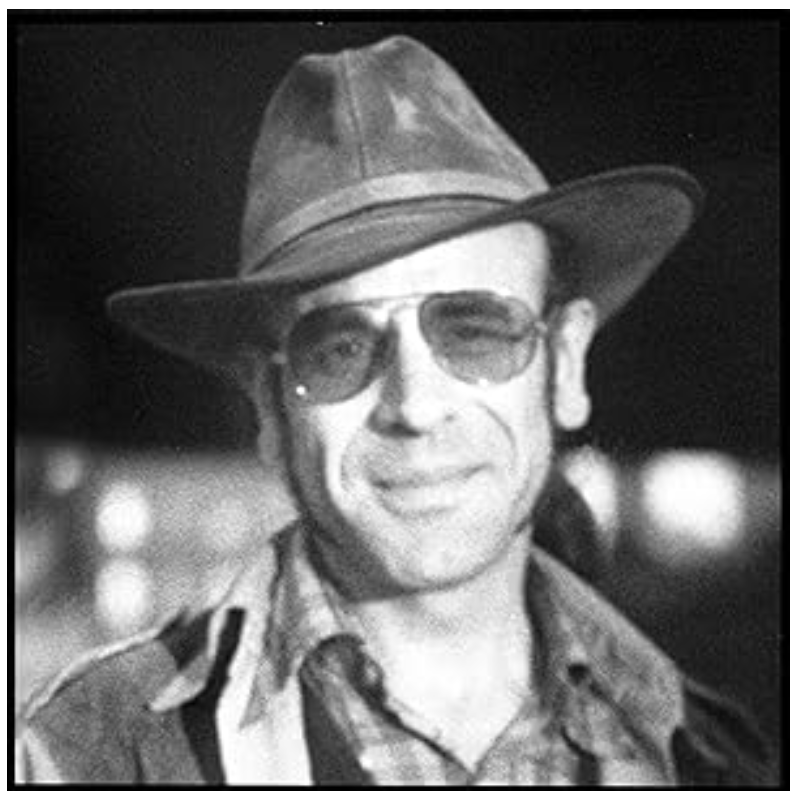

I purchased a composing stick and a set of individual type on Ebay to serve as examples:

Type is loaded “upside down … from left to right” (https://www.youtube.com/watch?v=AHrLIVeH1KM) and shown close-up below: (“Joseph” “Papin” “Artist”)

Leave a Reply